To ensure that every cup of coffee offers the best possible taste experience, enormously meticulous work is carried out in the growing countries. The green coffee undergoes intensive quality controls at every stage of the process. These controls begin in the field and only end when the green coffee leaves the warehouse in the growing country. The control process is as follows:

1. Only ripe cherries are picked

Quality control begins at the harvest. Only perfectly ripened coffee cherries provide the high-quality beans that are later processed into excellent coffee. In almost all of the regions we work with, the harvest is done by hand. This allows the workers to pick only the cherries that have reached the ideal level of ripeness.

This means that the pickers have to walk around all the bushes several times, as not all the cherries are always perfectly ripe at the same time.

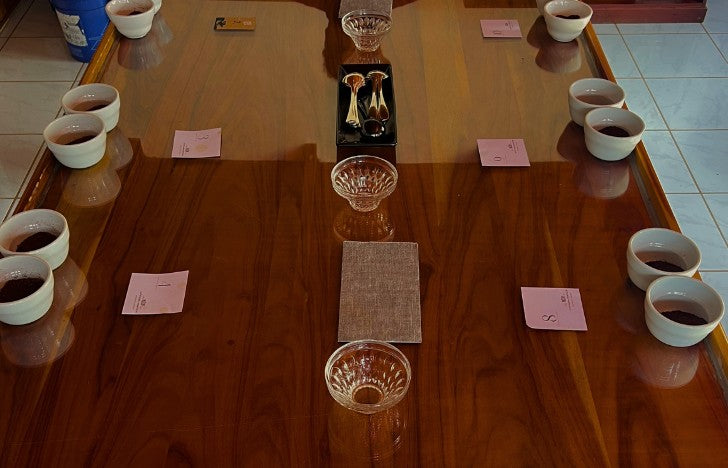

2. Cupping to determine the potential

Once at the processing stations, samples of the beans are taken and checked for defective beans. The defective beans are sorted out manually, the defect-free sample is roasted and then a cupping is carried out to determine the coffee's best potential. This is where it receives its first SCA score.

3. Sorting by size and weight

Meanwhile, the bags of the entire harvest continue to be sorted. In most cases, this is done by machine, only rarely by hand - depending on the local possibilities.

The beans go through several processes that classify them according to size, density and weight. If a bean cannot be classified, it is automatically put through the process again.

Larger beans (larger screen size) are of higher quality than small ones and heavy beans are of higher quality than light ones (higher density).

UV light inspection for defects

Some very advanced, technologically advanced facilities use UV light machines to detect defects and automatically sort out those beans, but most of the time this is done entirely manually in the next step.

4. Manual testing: intensive detailed work

This is the step that triggers an extreme appreciation for high quality.

Despite modern machines (including UV light machines), manual inspection is an indispensable part of the quality process. Before the beans are actually prepared for transport, each one is checked again by hand for defects - and if there are any, sorted out. This is really incredibly intensive work and such a great sign of quality. UV light is then used manually if necessary to identify defects even better.

5. Release for shipping: The final "go"

The final step of quality control occurs just before the coffee leaves the warehouse. Here, each batch is checked again before it is shipped. Samples are taken to ensure that the coffee has survived the storage process undamaged and is ready to make its way to us.

Conclusion: That is why we want to highlight the origin

Through our close collaboration with the farmers and our on-site visits, we have confidence in this process and know that every bean that leaves the warehouse meets the highest quality standards.

The most important:

Quality is created long before we pour the green coffee into our roaster. That is precisely why we try to create appreciation and gratitude for this huge effort with everything we do.